-

APP Client

Scan to download the app Easy procurement source

William Wang

William Wang

| US $ 15385.65 | Stock: 90000 | - + |

Product Description

Palletizing robot is a kind of machine device used to automatically perform work, in use it can accept human command, and can correctly run pre-programmed programs, can act according to the principles formulated by artificial intelligence technology, the objects that have been loaded into the container, according to a certain arrangement of stacks on pallets, pallets (wood, plastic), automatic stacking, can be stacked multiple layers, and then pushed out, convenient for forklifts to the warehouse for storage. Its purpose is to assist or replace human repetitive work, such as production, construction, etc.

Main advantages of palletizing robots:

01· The palletizing capacity of palletizing robots is much higher than that of traditional palletizers and manual palletizing;

02· The structure is very simple, the failure rate is low, and it is easy to maintain and repair;

03· The main components are few spare parts and maintenance costs;

04· Low power consumption, which is about one-fifth of that of mechanical palletizers.

05· The palletizing robot arm can be set in a narrow space, with high site efficiency and flexible application;

06· All operations can be carried out with a touch on the control cabinet screen and are very easy to operate.

07· The application of the palletizing robot arm is very flexible, and one robot arm can handle different products from up to 6 production lines at the same time. When the product is updated, only new data needs to be entered, recalculated and can be run, without the need for hardware or retrofit settings on the device.

08· The stacking type and the number of stacking layers can be set arbitrarily, and the stacking type is neat, which is convenient for storage and transportation.

Commonly used palletizing robot hand grip:

(1) Gripper manipulator claw: mainly used for high-speed code bags;

(2) Splint manipulator claw: mainly suitable for palletizing boxes and boxes;

(3) Vacuum suction manipulator: mainly suitable for suction stacked objects;

(4) Hybrid gripping manipulator: mainly suitable for suckable stacked objects;

(5) Hybrid gripper gripper: suitable for collaborative pick-and-place at several stations.

Application

Palletizing robots can be integrated in any production line to provide intelligent, robotized and networked production sites, which can realize the palletizing logistics of various operations in the beer, beverage and food industries, and are widely used in cartons, plastic boxes, bottles, bags, barrels, film packaging products and filling products. Equipped with three-in-one filling line, etc., to palletize all kinds of bottles, cans and bags. The automatic operation of the palletizer is divided into automatic box feeding, box transfer, rowing, stacking, pile transfer, stacking, stacking, pile-up, feeding, stacking, depalletizing and other steps.

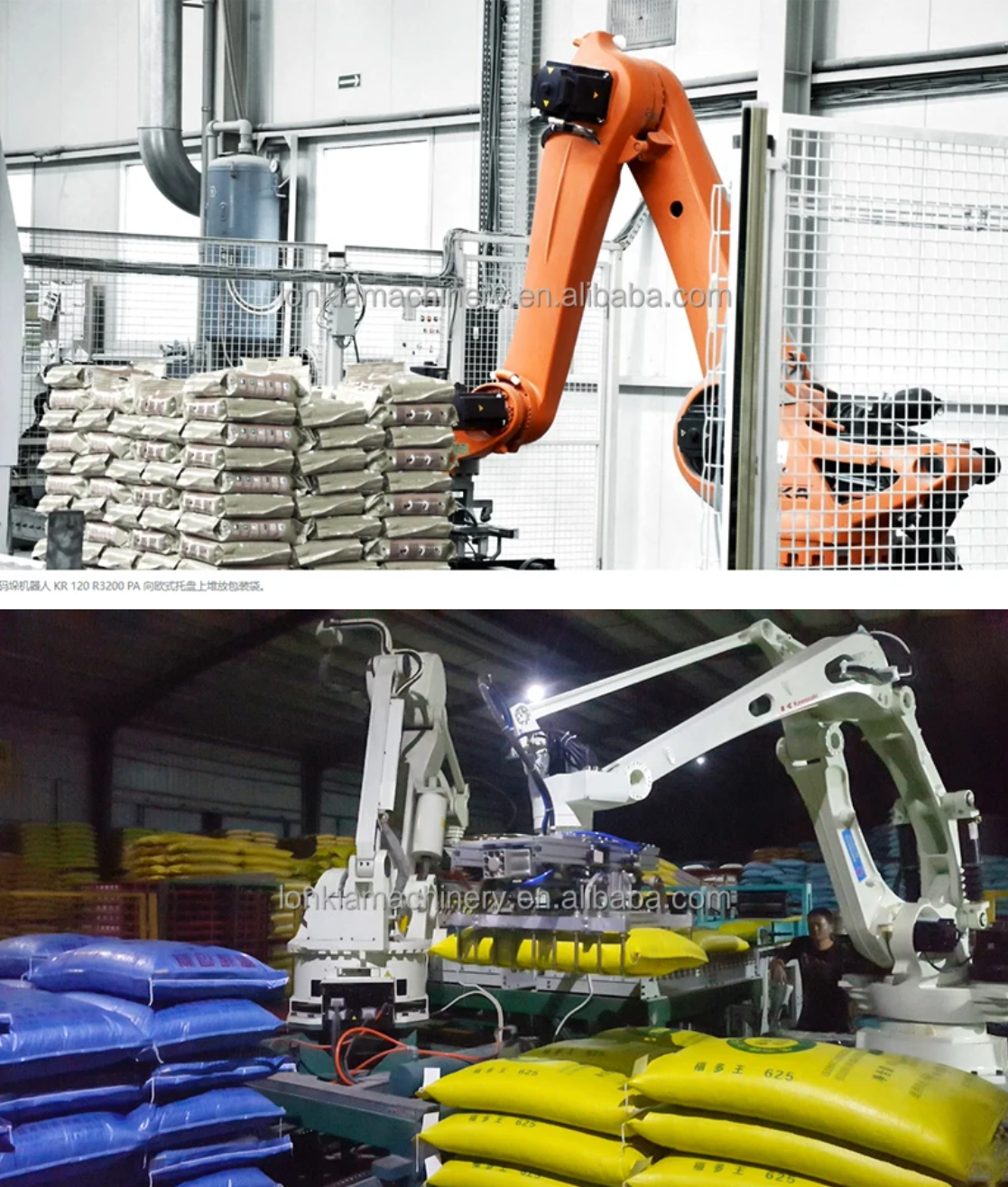

Case show

Product Photography

Company Profile

Shipping & Packing:

Standard export wooden case packing, fit for multiple handing and long distance marine shipping.

Delivery Time:

For stock type, we can send within 48hrs after confirming order.

For customized type , delivery date need to be negotiated before taking order.

FAQ

Q:1. What's the delivery time?

A: We will deliver the product in 7-21 days after receiving the deposit.

Q:2. What's your payment terms?

A:We can accept various payment terms if it is convenient for you.

Q:3. what's your MOQ?

A:Our MOQ is 1 piece.

Q:4. What's the lifetime of the wearing parts?

A:We provide three years warranty of core components.

Q:5. What is your warranty?

A:We provide 3 years except the spare parts.

Q:6. Will you send engineers to install the plant?

A:Of course yes, but at an extra cost will be paid by customers. Or you can get local contractors to do the commissioning and we send one supervising engineer.